In the era of smart manufacturing and automation, fluid control systems have evolved far beyond manual operation. At the heart of many of these systems lie brass actuated valves. Combining the robustness of brass with modern actuation technologies, these valves provide reliable, automated control for a variety of industrial applications.

The Need for Automation

Industrial processes increasingly demand speed, precision, and safety. Manual valve operation, while still used in some settings, cannot meet the demands of real-time control. Brass actuated valves step in by automating flow regulation, reducing human error, and enhancing operational efficiency.

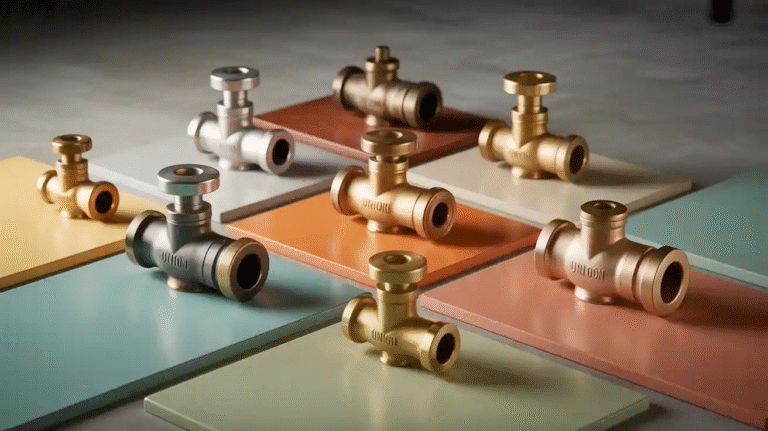

Types of Brass Actuated Valves

Following are the types of Brass Actuated Values:

Brass Electric Actuated Valve

A brass electric actuated valve uses an electric motor to control the valve’s position. It’s ideal for systems that require frequent and precise adjustments, such as in chemical dosing or HVAC zoning.

Brass Pneumatic Actuated Valve

This valve type is powered by compressed air and is well-suited for environments where electricity might pose a hazard. The brass pneumatic actuated valve is known for quick operation and long-term reliability.

Brass Air Actuated Valve

Similar to pneumatic systems, brass air actuated valves utilize compressed air for motion. They are commonly found in air handling systems, packaging machines, and automated assembly lines.

Integration with Modern Systems

Brass actuated valves are often integrated into programmable logic controllers (PLCs), SCADA systems, and IoT-based platforms. This integration allows for:

- Remote operation

- Real-time monitoring

- Predictive maintenance alerts

Why Choose Brass for Actuated Valves?

- Excellent thermal conductivity for temperature-sensitive systems

- Corrosion resistance prolongs lifespan in fluid-heavy environments

- Strength and machinability allow for durable valve construction

Use Cases

- Water Treatment Facilities: Automated flow regulation of chemicals and clean water

- HVAC Systems: Zoning and climate control

- Pharmaceutical Manufacturing: Sterile, precision fluid handling

- Food Processing: Compliance with safety standards and ease of cleaning

Cost-Effectiveness of Brass Valves

Compared to stainless steel or specialized alloys, brass provides an economical balance of strength, corrosion resistance, and ease of manufacturing. When paired with actuators, brass valves become a smart investment for scalable automation.

Installation and Maintenance

Most brass actuated valves are designed for straightforward installation. Maintenance often involves checking actuator connections, cleaning valve internals, and ensuring the valve seat remains sealed.

Future Trends

- Integration with AI for intelligent decision-making

- Wireless actuation and control via apps

- Energy-efficient actuators that reduce operational costs

Conclusion

Brass actuated valves are vital components in modern smart systems. Whether electric, pneumatic, or air actuated, these valves deliver the precision and durability needed in high-demand settings. As industries continue to move toward automation, the brass actuated valve, especially the brass electric actuated valve and brass pneumatic actuated valve, will remain central to efficient, scalable fluid control solutions.